Hydraulic Double Die Paper Plate Machine

Home-> products-> hydraulic-double-die-paper-plate-machine

Hydraulic Double Die Paper Plate Machine

A Hydraulic Double Die Paper Plate Machine is a type of industrial machinery designed to produce paper plates using hydraulic pressure. Paper plate machines are commonly used in the food industry, events, and other settings where disposable plates are needed. Let's break down the key components and functions of this type of machine:

1. Hydraulic System: The hydraulic system is a crucial part of the machine. It provides the necessary force to press the paper sheets into the desired shape. Hydraulic cylinders are used to apply pressure, which allows for precise and consistent shaping of the paper plates.

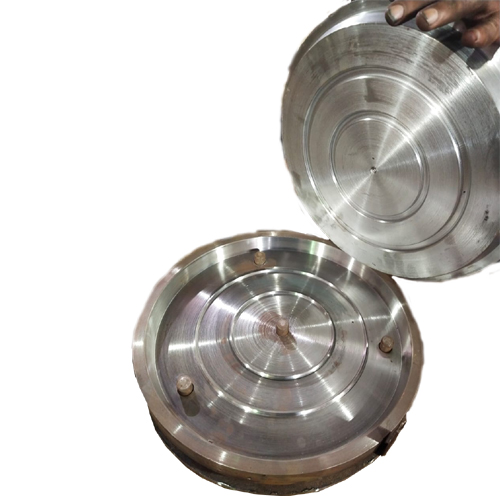

2. Double Die Configuration: The "double die" configuration means that the machine is equipped with two sets of dies or molds. Dies are the templates that shape the paper into the final plate form. With a double die setup, the machine can produce two paper plates simultaneously in each cycle, thereby increasing the production efficiency.

3. Paper Feeding Mechanism: The machine has a mechanism for feeding paper sheets into the press area. These paper sheets are typically pre-cut circular or oval shapes that will be molded into the final plate shape.

4. Heating Elements: Some paper plate machines also incorporate heating elements. These elements heat the paper sheets during the pressing process, which helps to set the shape of the plates and also aids in achieving a smoother finish.

5. Control Panel: Modern machines often have a control panel that allows the operator to adjust settings such as pressure, temperature (if applicable), and cycle times. This ensures that the machine operates efficiently and produces consistent results.

6. Safety Features: Safety features are important in any industrial machinery. Paper plate machines may include features like emergency stop buttons, safety guards, and sensors to prevent accidents and injuries during operation.

7. Output Conveyor: After the plates are pressed and formed, they are typically carried away from the machine on an output conveyor. This conveyor facilitates the collection of the finished plates.

8. Maintenance and Operation: Proper maintenance and operator training are essential for the smooth functioning of the machine and to ensure the quality of the produced paper plates.

These machines are used by businesses that need a large quantity of disposable paper plates, such as catering services, event planners, and food packaging companies. The double die configuration speeds up the production process, making it more efficient than single-die machines. As with any industrial equipment, it's important to consider factors like machine capacity, production speed, quality of output, and maintenance requirements when selecting the right machine for a specific business's needs.

Hydraulic Double Die Paper Plate Machine

Rs 1.6 Lakhs / UnitGet Latest Price

| Automation Grade | Automatic |

| Material | Mild Steel |

| Max Plate Size | Up to 14 inch |

| Capacity | 49 Pieces/Hour |

| Paper Material | Aluminium Foil Paper |

| Frequency | 50Hz |

| Power Source | Electric |

| Warranty | 1 Year |

| Voltage | 240V |

| Electric Motor | 2 hp |

| Phase | Single |

| Number Of Dies | 2 |

| Country of Origin | Made in India |

Hydraulic Double Die Paper Plate Machine