Semi Automatic Hydraulic Paper Plate Machine

Home-> products-> semi-automatic-hydraulic-paper-plate-machine

Semi Automatic Hydraulic Paper Plate Machine

A Semi Automatic Hydraulic Paper Plate Machine is a type of industrial machinery that combines both manual and hydraulic operations to manufacture paper plates. It offers a balance between automation and human intervention, making it suitable for medium-scale production of paper plates. Here's an overview of how a semi-automatic hydraulic paper plate machine works:

1. Semi-Automatic Operation: Unlike fully manual machines, semi-automatic machines involve both manual and automated processes. While some steps are automated, others require manual intervention.

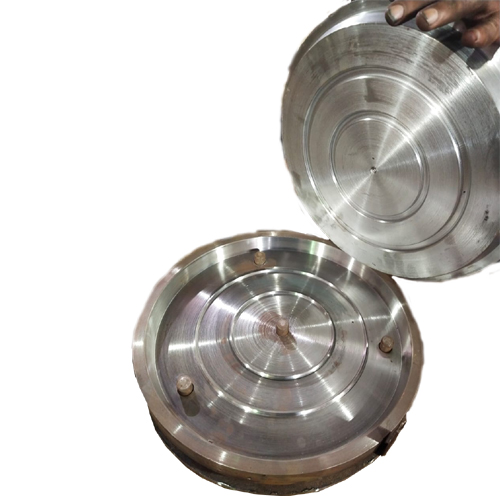

2. Hydraulic System: These machines incorporate a hydraulic system to apply pressure for shaping the paper plates. Hydraulic cylinders are used to press the paper sheets into the desired shape with consistent pressure.

3. Hydraulic Control: The hydraulic system is controlled by the machine itself, which helps ensure uniform pressure and accurate shaping of the plates.

4. Paper Feeding: The operator manually feeds pre-cut paper sheets into the machine. These sheets are typically circular or oval in shape and are placed over the molds or dies.

5. Pressing Process: Once the paper sheet is in place, the operator initiates the pressing process. The hydraulic system then applies pressure to the paper sheet, shaping it into the desired plate form.

6. Ejection: After the pressing process is complete, the machine may have an automated ejection system that pushes the formed paper plate out of the mold. Alternatively, the operator might manually remove the plate from the mold.

7. Repeat Process: The operator repeats the process for each paper sheet, creating one paper plate at a time. This semi-automatic approach is more efficient than fully manual methods.

8. Control Panel: These machines often come with a control panel that allows the operator to adjust parameters such as pressure, cycle times, and other settings for consistent production.

9. Size and Design: The size and design of the paper plates that can be produced depend on the machine's mold or die configuration.

10. Moderate Production Capacity: Semi-automatic hydraulic paper plate machines are designed for medium-scale production needs. They offer higher efficiency compared to manual machines but might not match the production speed of fully automated hydraulic machines.

11. Operator Involvement: While the machine automates some of the processes, it still requires an operator to feed paper sheets, monitor the operation, and remove the finished plates.

Semi-automatic hydraulic paper plate machines are suitable for businesses that require a moderate quantity of paper plates and want to achieve a balance between automation and cost-effectiveness. These machines are often found in small to medium-sized manufacturing setups, catering services, and event management businesses. When considering a semi-automatic hydraulic paper plate machine, factors like production capacity, plate size and design options, ease of operation, maintenance requirements, and the availability of spare parts and technical support should be taken into account.

Semi Automatic Hydraulic Paper Plate Machine

Rs 85,000 / UnitGet Latest Price

| Automation Grade | Semi-Automatic |

| Material | Mild Steel |

| Max Plate Size | Up to 12 inch |

| Capacity | 56 Pieces/Hour |

| Paper Material | Aluminium Foil Paper |

| Frequency | 50Hz |

| Power Source | Electric |

| Warranty | 1 Year |

| Voltage | 240V |

| Electric Motor | 2 hp |

| Phase | Single |

Semi Automatic Hydraulic Paper Plate Machine